Kamoo e Sebetsang Kateng

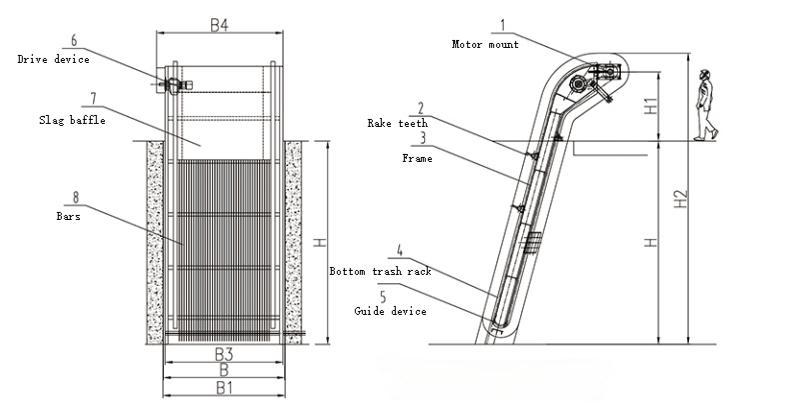

Ha metsi a litšila kapa metsi a tala a feta skrineng, lithōle tse kholo ho feta sebaka sa skrine lia tšoasoa. Meno a rake a poleiting ea rake e nang le meno a kenella likheong tse pakeng tsa mekoallo e tsitsitseng, a phahamisa thepa e thibeletsoeng holimo ha yuniti ea drive e potoloha ketane ea ho hula.

Hang ha meno a ho lahla a fihla moo a ntshang teng, ditshila di wela tsamaisong ya ho tsamaisa dintho ka lebaka la matla a khoheli bakeng sa ho di tlosa kapa ho di lokisa hape. Ts'ebetso ena ya ho hlwekisa ka boiketsetso e netefatsa tshebetso e tswelang pele le e sebetsang hantle ka thuso e fokolang ya letsoho.

Likarolo tsa Bohlokoa

-

1. Sistimi e Tšepahalang ea Drive

-

E kgannwa ke cycloidal pinwheel kapa helical gear motor

-

E na le lerata le tlase, sebopeho se senyenyane, le ts'ebetso e tsitsitseng

-

-

2. Meno a Boima a Rake

-

Meno a nang le ntlha e bevel e tjheseditsweng a kentswe hodima shaft e tshekaletseng

-

E khona ho phahamisa lithōle tse matla tse kholo ka katleho

-

-

3. Moralo o Matla oa Foreimi

-

Sebopeho sa foreimi se kopaneng se netefatsa ho tiea ho hoholo

-

Ho kenya habonolo ka litlhoko tse fokolang tsa tlhokomelo ea letsatsi le letsatsi

-

-

4. Ts'ebetso e Bonolo ho Basebelisi

-

E tšehetsa taolo ea sebakeng seo kapa ea hole bakeng sa ts'ebetso e tenyetsehang

-

-

5. Tšireletso ea Tšireletso e Habeli

-

E na le li-cutting pins tsa mechine le tšireletso ea motlakase o feteletseng

-

E thibela tšenyo ea lisebelisoa nakong ea maemo a feteletseng

-

-

6. Sistimi ea Grating ea Bobeli

-

Skrine ea bobeli e kentsoe botlaaseng ba yuniti

-

Ha meno a rake a tloha ka morao ho ea ka pele ho skrine se seholo, grating ea bobeli e kena ka bo eona ho thibela phallo ea ho feta le ho netefatsa hore ho tšoaroa ha lithōle ka katleho.

-

Likopo

-

✅Litsi tsa tlhokomelo ea metsi a litšila tsa masepala le tsa indasteri

-

✅Metsi a noka le liteishene tsa ho pompa metsi ka metsi a hydraulic

-

✅Tlhahlobo e khohlahetseng pele ho diyuniti tsa ho sefa tse tshekaletseng

-

✅Mehato ea pele ho kalafo lits'ebetsong tsa phepelo ea metsi

Li-parameter tsa Tekheniki

| Mohlala | HLBF-1250 | HLBF-2500 | HLBF-3500 | HLBF-4000 | HLBF-4500 | HLBF-5000 |

| Bophara ba mochini B(mm) | 1250 | 2500 | 3500 | 4000 | 4500 | 5000 |

| Bophara ba kanale B1(mm) | B1=B+100 | |||||

| Boholo ba letlooeng b(mm) | 20~150 | |||||

| Sekhutlo sa ho kenya | 70~80° | |||||

| Botebo ba kanale H(mm) | 2000~6000 (Ho ea ka tlhoko ea moreki.) | |||||

| Bophahamo ba ho ntsha metsi H1(mm) | 1000~1500 (Ho ea ka tlhoko ea moreki.) | |||||

| Lebelo la ho matha (m/Min) | Hoo e ka bang 3 | |||||

| Matla a enjene N(kW) | 1.1~2.2 | 2.2~3.0 | 3.0~4.0 | |||

| Moroalo oa tlhoko ea boenjiniere ba sechaba P1(KN) | 20 | 35 | ||||

| Tlhokeho ea boenjiniere ba sechaba P2(KN) | 20 | 35 | ||||

| Moroalo oa tlhoko ea boenjiniere ba sechaba △P(KN) | 2.0 | 3.0 | ||||

Hlokomela: P1(P2) e balwa ka H=5.0m, bakeng sa 1m e 'ngoe le e 'ngoe H e eketsehileng, ebe kakaretso ea P=P1(P2)+△P

Litekanyo

Sekhahla sa Phallo ea Metsi

| Mohlala | HLBF-1250 | HLBF-2500 | HLBF-3500 | HLBF-4000 | HLBF-4500 | HLBF-5000 | ||

| Botebo ba metsi pele ho skrine H3 (mm) | 3.0 | |||||||

| Sekhahla sa phallo (m/s) | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | ||

| Boholo ba letlooeng b (mm) | 40 | Sekhahla sa phallo (l/s) | 2.53 | 5.66 | 8.06 | 9.26 | 10.46 | 11.66 |

| 50 | 2.63 | 5.88 | 8.40 | 9.60 | 10.86 | 12.09 | ||

| 60 | 2.68 | 6.00 | 8.64 | 9.93 | 11.22 | 12.51 | ||

| 70 | 2.78 | 6.24 | 8.80 | 10.14 | 11.46 | 12.75 | ||

| 80 | 2.81 | 6.30 | 8.97 | 10.29 | 11.64 | 12.96 | ||

| 90 | 2.85 | 6.36 | 9.06 | 10.41 | 11.70 | 13.11 | ||

| 100 | 2.88 | 6.45 | 9.15 | 10.53 | 11.88 | 13.26 | ||

| 110 | 2.90 | 6.48 | 9.24 | 10.62 | 12.00 | 13.35 | ||

| 120 | 2.92 | 6.54 | 9.30 | 10.68 | 12.06 | 13.47 | ||

| 130 | 2.94 | 6.57 | 9.36 | 10.74 | 12.15 | 13.53 | ||

| 140 | 2.95 | 6.60 | 9.39 | 10.80 | 12.21 | 13.59 | ||

| 150 | 2.96 | 6.63 | 9.45 | 10.86 | 12.27 | 13.65 | ||