Video ea Sehlahisoa

Shebella kamoo Static Screen ea rona e sebetsang kateng bakeng sa karohano e sebetsang ea mokelikeli o tiileng.

Lisebelisoa

The Static Screen e sebelisoa haholo liindastering tse fapaneng bakeng sa ho hloekisa metsi a litšila le ho khutlisa lisebelisoa:

-

1. Ho etsa lipampiri, pulp & faeba ho hlaphoheloa- ho tsosolosa likhoele le ho tlosa lintho tse tiileng.

-

2. Libaka tsa mahlabelo, li-tanneries- ho tlosa lintho tse tiileng tse kang boea, mafura, mekotla le litšila.

-

3. Phetoho ea lijo le lino- ho hloekisa metsi a litšila ka har'a tsoekere, veine, starch, biri le 'mela ka ho tlosa likhoele tsa limela, likotoana, likala, joalo-joalo.

-

4. likhoerekhoere tsa masepala & phepelo e nyane ea metsi- pheko ea metsi a litšila a malapeng kapa a sechaba.

-

5. Noka dredging & sludge kalafo- karohano e tiileng-metsi mererong ea tikoloho.

-

6. Textile, petrochemical, khatiso & dae- ho hlaphoheloa le ho phekola pele ho tlosa lintho tse tiileng tse emisitsoeng.

Likarolo tsa Bohlokoa

✅Li-Screen Plates tsa boleng bo holimo- E entsoe ka tšepe e sa hloekang e entsoeng ka seam-welded e nang le matla a phahameng a mochine, e sa senyeheng le e hanyetsanang le crack.

✅Ts'ebetso ea ho Pholosa Matla- E sebelisa matla a khoheli, ha e hloke tšebeliso ea matla.

✅Tlhokomelo e tlase- Ho hlatsuoa ka letsoho nako le nako ho boloka likheo tsa skrine li hlakile ebile li sebetsa hantle.

✅Khetho ea Mohlala- Sehlopha ha se mamelle meroalo e tšosang; kamehla khetha mohlala o nang le matla a maholo ho feta lebelo la phallo e phahameng.

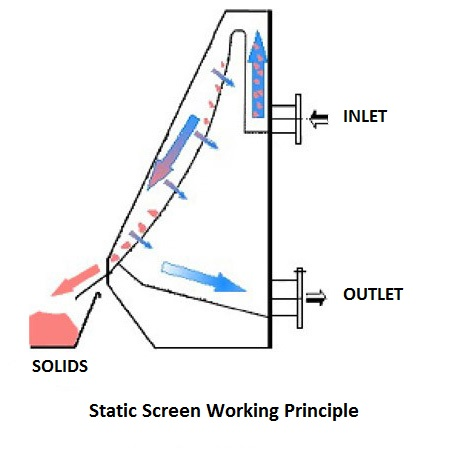

Molao-motheo oa ho Sebetsa

Karolo ea mantlha ea Skrini sa Static ke sekirini sa terata e sephara kapa se bopehileng joaloka arc se entsoeng ka lithupa tsa tšepe. Metsi a litšila a phalla ka ho lekana holim'a skrine e sekametseng ka har'a moqomo o phoroselang. Ka lebaka la sebaka se boreleli le likheo tse pharaletseng ka morao, drainage e potlakile mme ho koala hoa fokotseha. Li-solids li bolokoa le ho sutumelletsoa tlase ka matla a haeteroliki bakeng sa ho tsoa, ha metsi a hloekileng a feta, ho fihlela karohano e tšepahalang ea metsi a tiileng.

Liindasteri tse Tloaelehileng

-

1. Litšilo tsa pampiri- ho hlaphoheloa ha fiber, ho tlosoa ha lintho tse tiileng tse emisitsoeng.

-

2. Tanneries- ho tlosoa ha boea, mafura, le masalla a mang.

-

3. Mahlabelo- lintho tse tiileng joalo ka mekotla, boea, mafura le litšila.

-

4. Metsi a litšila a masepala- ho hloekisa likhoerekhoere tsa malapeng.

-

5. Lifeme tsa starch, joala, tsoekere, biri le 'mela- ho tlosoa ha likhetla tsa limela, fiber, matlalo a 'mela.

-

6. Pharmaceutical & food processing- karohano ea mesaletsa ea litšila tse fapaneng.

-

7. Mapolasi a likhoho le mehlape- ho tlosoa ha moriri oa liphoofolo, moiteli, le litšila.

-

8. Litlhapi le ho sebetsa nama- offal, sekala, nama e halikiloeng, ho tlosoa mafura.

-

9. Lisebelisoa tse ling- litsi tsa masela, limela tsa lik'hemik'hale, lifeme tsa polasetiki, lithupelo tse kholo, lihotele le libaka tsa bolulo.

Tekheniki Parameters

| Mohlala & Tlhaloso | HLSS-500 | HLSS-1000 | HLSS-1200 | HLSS-1500 | HLSS-1800 | HLSS-2000 | HLSS-2400 | |

| Bophara ba skrine (mm) | 500 | 1000 | 1200 | 1500 | 1800 | 2000 | 2400 | |

| Bolelele ba skrine (mm) | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | |

| Bophara ba Sesebelisoa (mm) | 640 | 1140 | 1340 | 1640 | 1940 | 2140 | 2540 | |

| Kenya DN | 80 | 100 | 150 | 150 | 200 | 200 | 250 | |

| Phatlalatso ea DN | 100 | 125 | 200 | 200 | 250 | 250 | 300 | |

| Bokhoni @0.3mm Slot (m³/h) | Khoho ea likhoho | 7.5 | 12 | 15 | 18 | 22.5 | 27 | 30 |

| Bokhoni @0.5mm Slot (m³/h) | Khoho ea likhoho | 12.5 | 20 | 25 | 30 | 37.5 | 45 | 50 |

| Mmasepala | 35 | 56 | 70 | 84 | 105 | 126 | 140 | |

| Bokhoni @1.0mm Slot (m³/h) | Khoho ea likhoho | 25 | 40 | 50 | 60 | 75 | 90 | 100 |

| Mmasepala | 60 | 96 | 120 | 144 | 180 | 216 | 240 | |

| Bokhoni @2.0mm Slot (m³/h) | Mmasepala | 90 | 144 | 180 | 216 | 270 | 324 | 360 |

-

Spiral Grit Classifier | Lehlabathe le Grit Separato...

-

Sefa Mekotla bakeng sa Karohano e tiileng-metsi

-

Ho Arola Phofo ea Baktheria Bakeng sa Phekolo ea Metsi a Litšila

-

Advanced K1, K3, K5 Bio Filter Media bakeng sa MBBR S...

-

QJB Submersible Mixer bakeng sa Motsoako o Tiileng-Mokelikeli o...

-

Bacteria ea Halotolerant - Bioremed e tsoetseng pele ...