Kakaretso

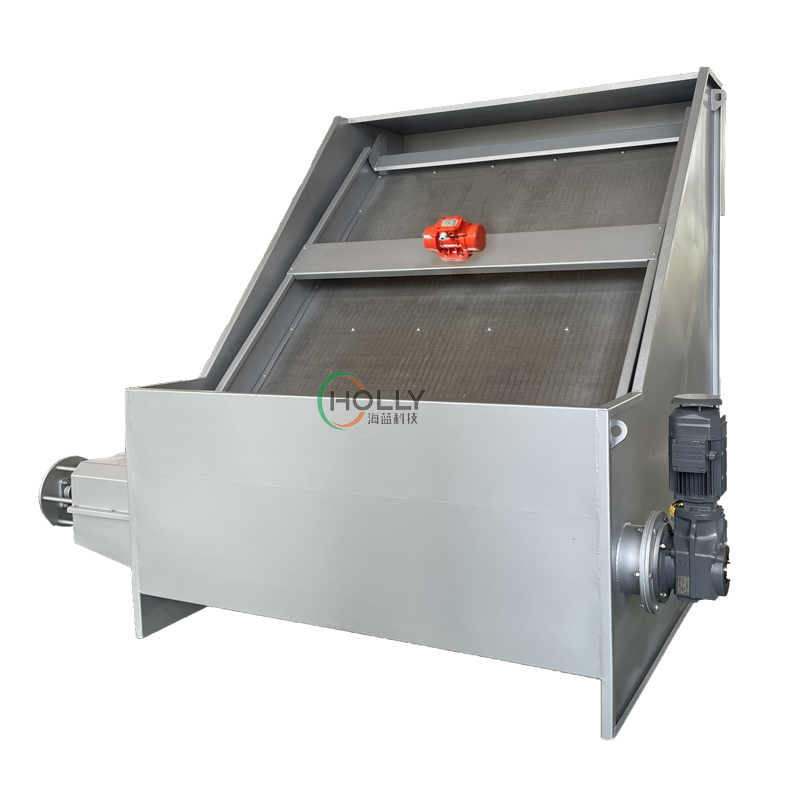

Skrine sa Static ke sesebelisoa se senyenyane sa karohano se se nang matla se sebelisetsoang ho sefa lintho tse tiileng tse emisitsoeng, lintho tse tiileng tse phaphametseng, li-sediments le lintho tse ling tse tiileng kapa tsa colloidal ho hloekisa likhoerekhoere kapa ho hloekisa metsi a litšila a indasteri.Ho sebelisoa sekirine sa tšepe e sa hloekang se bōpehileng joaloka sekhoakhoa se sebelisetsoa ho etsa bokaholimo ba sekirini sa arc kapa sefahleho sa sesefa se bataletseng.Metsi a lokelang ho hloekisoa a ajoa ka mokhoa o ts'oanang sebakeng sa skrine se sekametseng ka har'a moqomo o phoroselang, ntho e tiileng e ea haneloa, 'me metsi a hloekisitsoeng a phalla ho tloha lekhalo la skrine.Ka nako e ts'oanang, taba e tiileng e sutumelletsoa karolong e ka tlaase ea sejana sa sieve hore e lokolloe tlas'a ketso ea matla a hydraulic, e le ho finyella morero oa ho arohana.

Sesepa sa Static se ka fokotsa matla a emisitsoeng (SS) ka metsing le ho fokotsa boima ba ts'ebetso ea lits'ebetso tse latelang.E boetse e sebelisoa bakeng sa karohano ea metsi a tiileng le ho hlaphoheloa ha lintho tse molemo tlhahisong ea indasteri.

Kopo

◆ E sebelisoa ho etsa pampiri, ho hlajoa, letlalo, tsoekere, veine, ho lokisa lijo, masela, khatiso le ho daea, petrochemical le lisebelisoa tse ling tse nyenyane tsa metsi a litšila a indasteri, ho tlosa lintho tse tiileng tse emisitsoeng, lintho tse phaphametseng, sediments le lintho tse ling tse tiileng;

◆ E sebelisoa ho etsa pampiri, joala, starch, ho lokisa lijo le liindasteri tse ling ho tsosolosa lintho tse molemo tse kang fiber le slag;

◆ E sebelisoa bakeng sa phepelo e nyane ea metsi le phepelo ea metsi.

◆ E sebelisoa bakeng sa ho lokisa liretse esale pele kapa ho chesoa ha noka.

◆ Merero e fapaneng ea ho hloekisa likhoerekhoere tsa mefuta le boholo bo fapaneng.

Lintlha tse ka sehloohong

◆ Likarolo tsa filthara ea lisebelisoa li entsoe ka seam welded steel stainless screen plates, tse nang le litšobotsi tsa matla a phahameng a mochine, ha ho na deformation, ha ho na ho phunyeha, joalo-joalo;

◆ Sebelisa matla a khoheli a metsi ka booona ho sebetsa ntle le tšebeliso ea matla;

◆ Hoa hlokahala hore ka bowena u hlakole li-grid seams nako le nako ho thibela ho thibeloa;

◆ Thepa ha e na matla a ho hanyetsa meroalo e tšosang, 'me matla a ho sebetsa a mohlala o khethiloeng o lokela ho ba moholo ho feta phallo e phahameng.

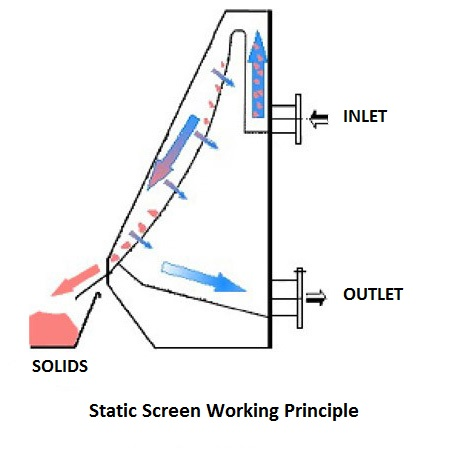

Molao-motheo oa ho sebetsa

'Mele o ka sehloohong oa skrine e tsitsitseng ke sekoahelo sa tšepe se bōpehileng joaloka arc kapa se sefa se bataletseng se entsoeng ka lithupa tsa tšepe tse bōpehileng joaloka wedge.Metsi a litšila a lokelang ho hloekisoa a ajoa ka ho lekana holim'a skrine e sekametseng ka har'a moqomo o phoroselang.Ka lebaka la sebaka se senyenyane le se boreleli sa skrine, lekhalo le ka morao le leholo.The drainage e boreleli 'me ha ho bonolo ho thijoa;ntho e tiileng ea thijoa, 'me metsi a hloekisitsoeng a phalla ho tsoa lekhalong la poleiti ea sieve.Ka nako e ts'oanang, taba e tiileng e sutumelletsoa karolong e ka tlaase ea sejana sa sieve ho tsoa tlas'a ketso ea matla a hydraulic, e le ho finyella morero oa karohano e tiileng-metsi.

Liindasteri tse tloaelehileng tsa kopo

1. Metsi a litšila a etsang lipampiri—a sebelisa fiber hape ebe o tlosa lintho tse tiileng.

2. Metsi a litšila a entsoeng ka matlalo—a ntša lintho tse tiileng tse kang boea le mafura.

3. Hlaba Metsi a litšila—Tlosa lintho tse tiileng tse kang mekotla, boea, mafura le mantle.

4. Likhoerekhoere tsa ka tlung—Tlosa lintho tse tiileng tse kang boea le lithōle.5. Joala, metsi a litšila a feme ea starch a tlosa likhetla tsa fiber ea semela, korosari le lintho tse ling tse tiileng.

6. Metsi a litšila a tsoang lifekthering tsa meriana le lifekthering tsa tsoekere—ho ntšoa ha lintho tse thata tse kang masala a litšila a sa tšoaneng le likhetla tsa limela.

7. Metsi a litšila a lifekthering tsa biri le ’mela—a tlosa lintho tse tiileng tse kang ’mela le letlalo la linaoa.

8. Mapolasi a likhoho le mehlape-ho tlosoa ha lintho tse tiileng tse kang moriri oa liphoofolo, mantle le mefuta e meng.

9. Litsi tsa tlhapi le nama - ho tlosoa ha lintho tse tiileng tse kang offal, sekala, nama e halikiloeng, grease, joalo-joalo. Tse ling tse kang ho hloekisoa ha likhoerekhoere tsa limela tsa lik'hemik'hale, limela tsa masela, limela tsa lik'hemik'hale, lifeme tsa polasetiki, mechine e meholo. limela, lihotele le libaka tsa bolulo.

Tekheniki Parameters

| Mohlala&Litlhaloso | HLSS-500 | HLSS-1000 | HLSS-1200 | HLSS-1500 | HLSS-1800 | HLSS-2000 | HLSS-2400 |

| Bophara ba Screenmm | 500 | 1000 | 1200 | 1500 | 1800 | 2000 | 2400 |

| Bolelele ba Screenmm | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 | 1800 |

| Bophara ba Sesebelisoamm | 640 | 1140 | 1340 | 1640 | 1940 | 2140 | 2540 |

| InletDN | 80 | 100 | 150 | 150 | 200 | 200 | 250 |

| SethalaDN | 100 | 125 | 200 | 200 | 250 | 250 | 300 |

| Khoho ea likhoho Bokhoni (m3/h) @0.3 limilimitharaSekotjana | 7.5 | 12 | 15 | 18 | 22.5 | 27 | 30 |

| Khoho ea likhoho Bokhoni (m3/h) @0.5mm SekotjanaMasepala | 12.5 | 20 | 25 | 30 | 37.5 | 45 | 50 |

|

| 35 | 56 | 70 | 84 | 105 | 126 | 140 |

| Khoho ea likhoho Bokhoni (m3/h) @1.0mm Sekotjana Masepala | 25 | 40 | 50 | 60 | 75 | 90 | 100 |

|

| 60 | 96 | 120 | 144 | 180 | 216 | 240 |

| Bokhoni (m3/h) @2.0mm SekotjanaMasepala | 90 | 144 | 180 | 216 | 270 | 324 | 360 |